Ferrari F40 LM Restoration Part 5

We’re pretty much at the business-end of the F40 LM restoration now. The body is buttoned up, fuel is flowing through the lines, and the turbos are spooling. Click below to see it take shape, including a couple of videos and a sneak peek at an EVO Magazine photoshoot. We are now up to date with the actual build thread on Ferrari Chat. At a guess I’d say updates from here on out will be evolution of the car in it’s final state, but I’ll be sure to make another post when the updates add up.

I’d like to take this opportunity to thank everyone for their clicks, comments and support during 2014 and hope you’ll stick around for yet another year of Build Threads

Previous F40 LM posts:

Part 1 – Part 2 – Part 3 – Part 4

Or, click here for the build index.

Dam partitions being hot glued into position (these will form the mould joints and also serve for the vacuum bagging)

An interesting series showing the process of one part of the mould being laid up.

Hopefully the dams / flanges in the 1st photos will now be self explanatory. Note the layer of green release agent which is applied over the waxed parts to further enhance mould release, also the registration female domes on the horizontal flange surfaces which will provide for the forming of male counterparts.

This second photo shows a stabilising layer of fibre glass lain over the tooling Gelcoat. This layer will cure overnight and then we lay another 5 layers in quick succession.

Mould now taking shape

Possibly my last post for a week which is a pity as hopefully this is the first dyno week so like you, I too am going to have to wait to hear the results. Fingers crossed.

A few of the ducts in process of being duplicated.

Briefly surfaced to hear first impressions are all going well on the dyno so far. More to follow in a few days.

And yes, camera crew were in attendance so video and better pics to follow in due course.

And for posterity!

Meanwhile on the mould front, major progress and James is back on the project applying Silicon sealer to the mould flanges so as to seal against air leaks when we finally have to pull the vacuum for the CF curing.

Forgive me all those who understand this process, but by way of explanation, this is a four piece mould with generous flanges which add strength and help combat warping, also some will be used to mount the vacuum piping. The green surface finish is ” Tooling” Gelcoat and is used in conjunction with ” Tooling” resin and whilst more expensive it has a low shrinkage rate which will help us remove the painted front hopefully without damage and it is tough and able to withstand high baking temperatures.James is applying a Silicon sealer between the mating surfaces of the jig so as to seal against air leaks when we pull the vacuum. Mr Brown is bolting everything together using 8 mm nuts and bolts, the dimples were moulded in to the flanges to aid register / alignment.Next up the first lay up.

James, having waxed the mould and applied spray release agent is now spray gluing/laying down the first layer of material which in this case is a 200 gram woven fibre glass. This will be our exterior painting surface and will give us some tolerance should we need to lightly sand out any imperfections and when impregnated along with the carbon, be completely invisible; next layer will be 200 gram Carbon Fibre.

Next phase uses this interesting honeycombe material which is used as the filling in a carbon sandwhich. The honeycombe media is closed cell and doesn’t absorb resin, remaining light weight; it’s interesting property is that each hexagonal cell is held together by small tags which leaves a tiny vertical alleyway between each cell which is then saturated with resin thus bonding the upper and lower Carbon Fibre laminates together providing an incredibly light and stiff piece.

First layer of carbon being laid up and honeycomb being sized.

Hopefully we should be infusing the resin next week

Another shot showing the covered green butyl strips which will retain the vacuum in due course.

Update on the mechanical side of things having now spoken in more detail to those whom were there on Dyno day, and we have agreed a plan.It was somewhat of an un intended result that we actually got that 604 reading, regardless of the ensuing discussion, as that was not the point of the session. The real point was to ensure that we had successfully integrated the Motec installation with our new engine and turbo set up, that all was good on the engine installation and know we are producing adequate power. That told us we need to fit new injectors to get enough fuel into the cylinders for when we ramp the boost up and go for power. If we fit the injectors now, we will have to have another dyno session just to get the engine to run satisfactorily, but with so few hours on the new motor, we would not be in a position to do a full power run. In short, pointless.Consequently, we have decided to finish off the car and actually get it on the track for a limited shakedown and see what other issues we have to resolve. We then need to get a total of say 600 miles or so under our belt to ensure the motor is properly bedded in.After that we will fit the new injectors and return to the dyno for a full power session, turning up the boost and revs, as right now we have kept it low so as to minimise stress on all components. We also have to decide where to fix our rev limit, 7,500 being safe, but we are pretty confident we can go further, again something for the later session. I am thinking 8,000.Overall the plan after a hard and expensive 20 months is softly softly, tempting though it may be to rush things and just go for a big dyno figure.

First of a series of pics showing the three ” sacrificial layers ” being laid down with spray glue, which will enable the expoy resin infusion.The 1st stripy material is a rip film, the 2nd layer is ” donut paper ” and the 3rd is a netting which maintains a space which aids resin flow when a vacuum is pulled. The butyl strip which will adhere the edges of the vacuum bagging is in place but covered with a protective tape to keep it clean.

Next element of the ongoing process

And now the piping to infuse the resin.

Just for interest, this is the cordless cutting tool used to trim the CF.

Test vacuum being pulled as you can tell by the compressed material

This pic shows James placing the activated resin into a vacuum chamber where any air will be removed from the agitated resin.

This pic shows the resin being tipped into the delivery tray.

And finally this pic shows the electronic vacuum gauge and a separate temp / humidity gauge …….. note the resin saturating in the background.

A quick break back to the car itself whilst the front clam resin goes off before it gets cooked.

And Colin fitting our new seats. Note the engine cross brace now finally installed.

MT put the old front clam on and went for a gentle trundle. Still lacking badges, Gurney flap etc and they won’t go until final paint prep and we get the new clam finished, but nice to finally have something approaching a finished car, or at least the end is very much in sight.

Piece has been baked in its mould for two hours, then through a cooling cycle, then back in the oven at a higher temp, then another cooling cycle then another baking at a higher temp still, finally out into the sunshine for a free cook off from the sunPrior to removing the new piece from the mould, all the sacrificial layers are removed, a MUCH tougher job than it looks.

Cleaning up and cracking open the mould

And first sight fresh out the mould

Green stuff is the release agent and will wash off. As you will see the fine layer of Fibre Glass has dissolved and you may just be able to see the subtle honey comb effect, which hopefully we reckon that by judicious prep and paint we can maintain. Now for all the other elements, wheel arches etc.

think some members pointed out that the routing of our oil pipe was less than elegant which scratched an itch I already had.Hopefully this is more to your liking?Also note the new wastegate heat shield.

The clam now with air conveyor etc trimmed.

8 Kilos for the front clam. Amazing and you are almost frightened to try and bend and push against it yet so strong.Yet another F40 in the shop for a fettle-really beautiful example.

New higher flow injectors arrived.

James starting to lay up the carbon wheel arches.

Had to wait a while for this

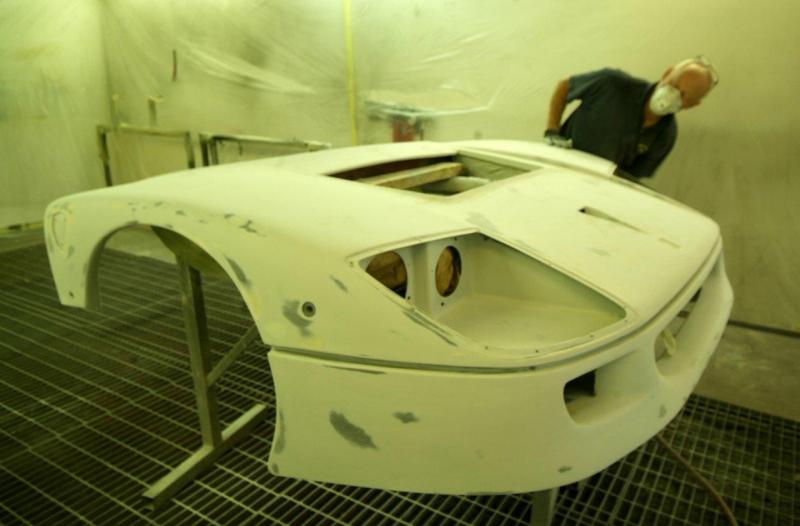

Back in the booth for all paintwork detailing

Meanwhile some more progress on the carbon arches.

and a couple of other shots showing part of the undertray as well as the arch.

Resin infused and cooking. This time, so as to ensure a perfectly flat surface, we have used glass as a base. Apologies if this is getting somewhat repetitive!

James working up the headlight recesses.

And cutting them in

Progressing…….

Just putting a bit of satin black on the air filter boxes rather than the gloss it was.

Headlight pods are now prepped and primed prior to fixing them into position as clearly impossible to do so once fitted.

And the rear clam now with the CF detailing mounted

Headlight pods being bonded in.

The aim is to hang on to it forever and never sell, but then one should never say never! Where am I going to find anything that looks like this again…….

Another shot, but the money shots are yet to comeAlso pls note air boxes are no longer gloss.

Meanwhile, back at the other end, new Braille battery finally sourced and fitted.

And another shot

Further work on the clam with James shaping up the floor panels.

I present the fabled and little known or seen F40 wiper motor.

Coming together.

Love the ease with which James lifts it.

OK, looks like it does fit and is sooo light but feels like it has great torsional rigidity. Hopefully the car will weigh in at just over the 1000KG mark, maybe 1050 or thereabouts.More typical MT scenery.

We had an Fchatter , Lindsey, visit today who is apparently one of our biggest fans on this project. Bothered to Schlepp all the way in on public transport from the other side of London to see what Kevin had going on in his workshop and especially the LM. Occasionally it really feels good to be doing this project seeing the pleasure it gives others.To top it off, Kevin took him out in his very special Dino(beautiful and unique GTS with, amongst other things, a 328 motor!) and apparently they had just the best time.

Bit of a quiet phase as Kevin is busy driving his GTS through Austria.Spot the deliberate mistake. I think the lads are doing it on purpose now…..

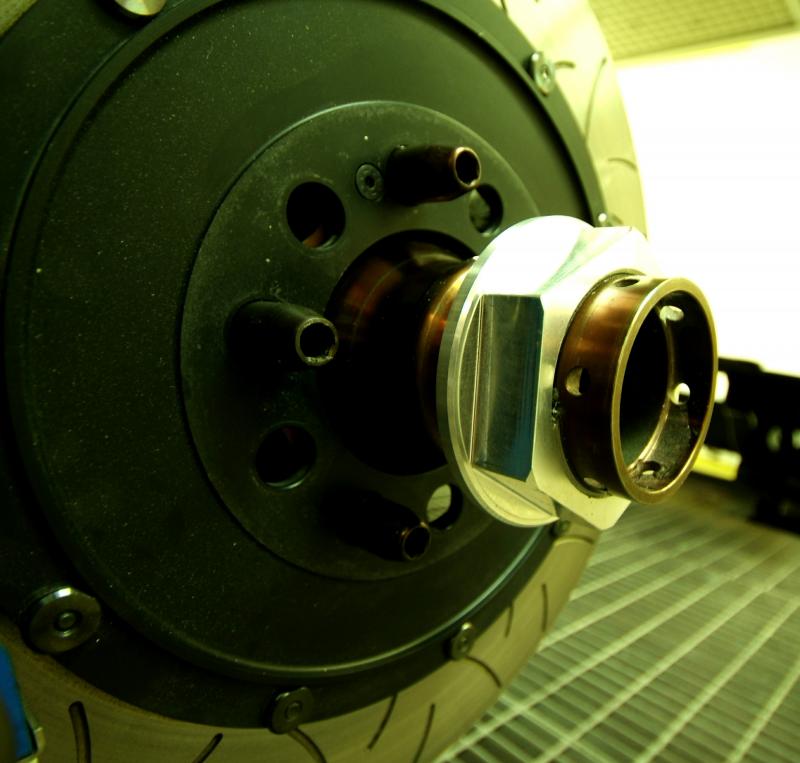

For some reason the standard wheel nuts don’t fit the Michelotto rims, the flange of the hub being different so the car is off to have this sorted as well as some further setting up work on the Motec with a company who have extensive experience campaigning an LM.

And off on another trip. If only the mileage counted.

Goodbye for a week or so

And James seemingly looking somewhat concerned and sad a5 losing his baby for a week or so……

James back in harness on the clam and he has completed the bonding of the inner ducts and prepped and primed it. Next step will be the fitting of the light lenses and then to sand ensuring there’s no pin holes or minor ripples. Then a final re-prime ready for colour but we need the car back for a final fit firstAll looks a little like Groundhog Day, until you go to pick it up.

New Perspex lenses being trimmed and fitted to the new clam which in turn has been sanded ready for the final coating of primer.

Well that was a struggle. F40 shields seem to be somewhat elusive, only left hand ones at the Factory, no pairs, but thanks to Lee and this Forum, (conveniently in Australia!), we now have a set and thus will be suitably attired for the Ball.

Headlight lenses being fitted for size.

Car back in 5 days, wheel nuts made and Motec work including fuel tank calibration underway, and then final paint and assembly for the 13th.Prep continues on the clam

A couple of somewhat repetitive shots showing new front clam being sanded and shaped and in the second the final application of 2 pack primer. Car returns Monday for the final, final preparation work and then we will paint the inner wheel arches black leaving the relevant areas in the natural carbon finish. 2 weeks to go.

Car back Monday pm, meanwhile an application of a ” Wet on Wet ” grey primer for the wheel arches to seal and loose fine sanding marks which will be followed by two coats of 2 pack Rally black. Hopefully by the time we have the car back, the clam will be finished aside from a final fitting check and then to paint.

And finished

After a last minute crisis, car is finally back and we can get on. New wheel nuts look good. More to follow as a hectic few days await.

Front clam getting final pre paint adjustments.

D-8 More of the same. Paint beckons.

D-7 Well we are really up against it to make the 13th now with just 5 working days to go and holidays to cope with so Kevin and the lads are having to pull out all the stops. Work continues on the clam.

A bit of colour back in the thread. Rear clam and doors back on, for the last time I hope.

Much detailing work on many aspects still to be done as the car is also being photographed on the 13th for a leading magazine.Front Clam still in primer – Nervous times.

Work continues on the front clam and hopefully colour later today (well we simply have to). Meanwhile detailed work being done on the old clam to establish correct position for the tow hook and in the background calibration of the fuel tank ongoing.As you can see, it is currently all hands to the pump.

We have been in discussions for so time but finally I have agreed an exclusive deal with EVO and they will be doing a major article which I think compliments the car and the project perfectly. I considered Top Gear but they are less ‘serious’ in my view and all Evo’s drivers for such a car are international standard racers with GT and endurance car experience and thus more likely to understand the car and get the best from it.It looks like we will have at least an element of the front cover and a minimum of 8 pages inside. In addition, there will also be an Evo video for YouTube.All very exciting and as I said, I think perfectly complements the quality and goals of the project.PS Still the old clam but new clam in paint as I type,

Going Red. Finally

Here we are working on the brakes.

Flooding you with images now as panic sets in. Manufacturing front the tow hook which then needs paint.

And the result pre paint.

Clam finally coming along.

Brake cooling trunking finally finished. Work of art to my eyes.

The fruits of a late night. Joe you were right.

Getting there

Last part to be made.

When viewed from the back, finished.The front is getting closer and will be done tomorrow.

Delicious or what?

Almost there

A couple of almost shots

Final

Well here you go, as finished as possible for tomorrow, still short of a few details but what a week for Kevin and the Lads, but they made it so a big thank you to them. Looking at the reflection in the clam that is clearly no factory effort!Hopefully more pics from Silverstone tomorrow.

Thanks everyone for your kind comments-the constant support is much appreciated.What a day! Given pride of place at the entrance with a Speciale and La Ferrari in the static display, second row behind two La Ferraris for the 650 car Parade, lunch with the CEO Ferrari Northern Europe, unbelievable and somewhat humbling reaction to the car, played on the F1 simulator, watched the F1, FXX’s and Pirelli Challenge and F12 home again. Simply put does it get any better? I think not.I never expected the reaction the car received and amazingly it seemed to draw more crowds than the neighbouring LFI will post some better pics once I download from my camera but a couple from my iPhone for now. One detail I noticed was that Mototechniques paint was second to none with a perfect finish and yet the weave still just grinning through. And it actually worked.Stoked.

2nd row but fair enough in this company

Couple of great additional images from Club Scuderia

Like the LF in the background

And finally

It wasn’t my imagination….

A few weekend shots

Parting of the red(and yellow) sea

All very exciting after all this time and again thanks to all for further kind comments. Surprisingly it all felt pretty good albeit at such slow speeds, and you can really feel the additional bite, and load, that those super wide 11.5 inch front tyres give and for sure they will provide a work out. Clutch is quite aggressive but felt better at the end of the day than the beginning and we need to give more modulation and progression to the brake pedal but I have a feeling this is going to be a monster, fingers crossed.Meanwhile a rushed interior shot. We are shortly hoping to fit name tags for the various switches and warning lights, a ‘horsey’ horn button and then the interior is pretty much done. Driving position seems to be just perfect for me (6ft 2+) but just as well we modified the runners at an early stage as now I have absolutely perfect sight of change up lights and instruments. LM seats felt great with excellent support and looked it too.As to where the shakedown is, that is currently in Evos hands but I will of course post when I know.

MotoT been busy sorting out a few issues including what was not apparent at Silverstone such as a few under front claim finishing details. We have also added a charging point as light though the front clam is, it is not a one man job to remove and I want to be able to attach a trickle charger easily.Still waiting to hear about the shakedown.

Another shot loading up which I forgot to post, Does this design really look 25 years old?

A few more shots from Facebook

Seemingly a tricky item to locate but finally, thanks to a generous follower on another site, we have the correct ‘horn’ button. Now looking like possibly a shakedown on Friday.

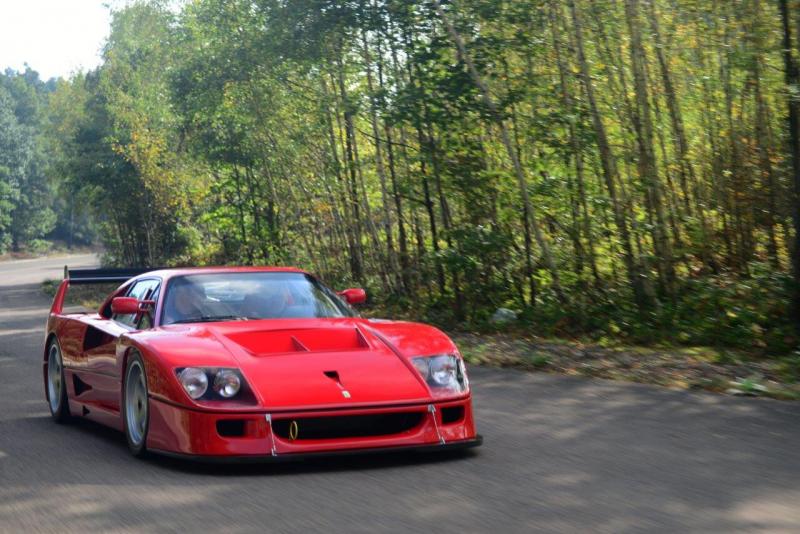

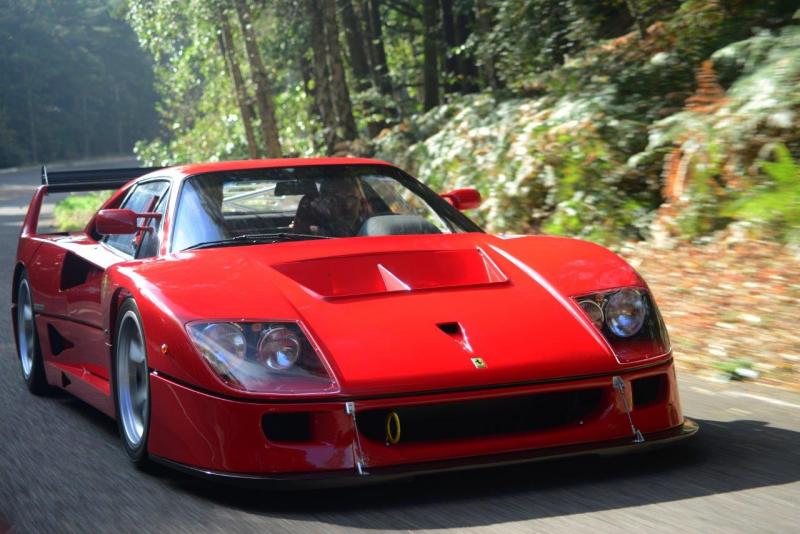

Indeed. A teaser from today…….

My favourite detail from today, but I suspect the Evo snapper will have done better.

A further teaser until I can report more fully this week and have access to something other than an ipad to post from

OK, bit more info and snaps from the day.We spent a few hours at Longcross and it was good that Colin drove the car there and back on trade plates as it was always a goal that it didn’t have to have a mothership in the shape of a transporter.

After some snaps and the sun finally making an appearance, John gradually worked it up on all fronts and amazingly it didn’t sound any louder than the Macca F1 on a Sports exhaust. I had a couple of laps with him where it felt very planted and just more of an F40 than a normal F40, the wider front end seemingly making a big difference in feel. Finally after my 60mph dash at Silverstone he started to put some pace into her and it felt great. Kevin asked him to be brutally honest as they are restorers rather than race technicians and basically he was happy with everything particularly the brakes and the steering and had no complaints at all, which is really a testament to everyone’s work from such a guru and encouraging for the next stage, not to say a relief. He just wanted more power which is incoming.Actually, to be truthful, I was just buzzing, in fact we all were after two years of graft, this was all we could have hoped for.Meanwhile a few more of my shots from the day and I will post some more including the F1 later on.

We are not finished yet! Few more additions to the car and later this week we start to swap the injectors which is not a short job, and then back to the dyno end next week to start to turn up the boost. That will be exciting. Then we have the full Anglesea Evo test. So that sounds to me like a Feb issue approx all being well, but still some hurdles to cross.First pics on the move.

A quick breather and some further detailed shots of the F1 that had come to watch!Beautiful car, beautiful condition, fitted, not I understand with an uprated engine, but with sports exhaust.

Happy days.

Labels just arrived for the dash and just being tried on for size with double sided tape and think they are just slightly too big; No cigar.Or leave blank with no labels as pretty obvious except on the other side where there are three switches which need identifying?

I think my final shot from the shakedown day.

Been here before but it all has to come off to get at the injectors.

Off with more to get at the fuel rails, all the while everything at risk of damage wrapped in tape

And our new high flow injectors.

Looking good

A rather better view of your tray….

and my car

Meanwhile turns out our injectors needed a bit of adjustment to fit but finally all going back together and looking delicious.

In more detail

And again.Dyno day looks like Monday so another major hurdle to overcome as we ramp the boost which will put Colin’s engine building skills under pressure!

And finally

All back in one piece and ready for Dyno Monday which we are videoing again and this time looking for more power.Meanwhile a couple of snaps of the front spoiler where we have covered the supports in black-one of a few more finishing touches to come.

And in close up

It has already been tested!

………

Meanwhile, after trying a number of sizes, we finally have, I think, the correct style and sized labels.

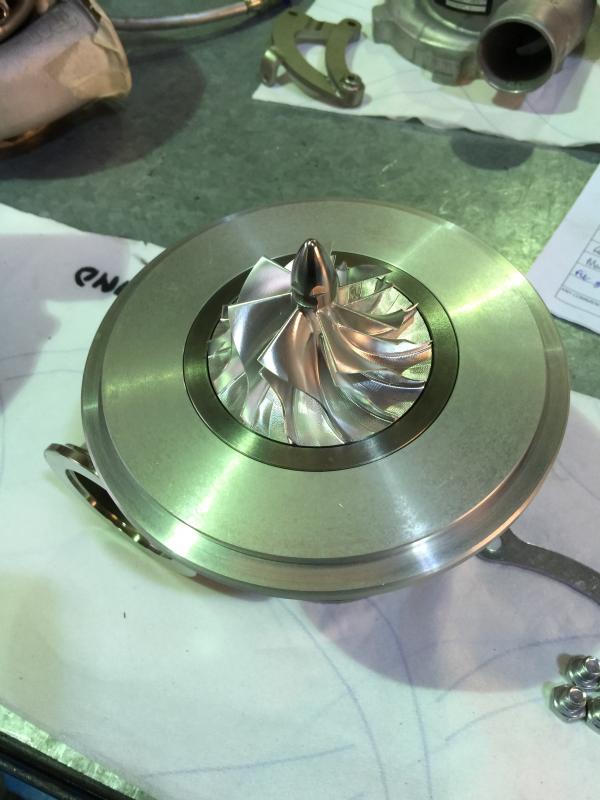

Our new specially built and modified turbos are ready and will be fitted next week and then we can return to the Dyno. All the work is being carried out by Mark at Owen developments and you simply could not get a more helpful service from a company that seems to be the leader of the pack here in the UK working for, amongst others, the Honda Racing team, championship rally teams and various BTCC winning teams including the 2013 championship winner.I just hope he is right in his diagnosis, which makese logical sense, but we do feel in safe hands. Also, seeing as how it is a no foal no fee arrangement, nothing much but time to lose.

Finishing up tomorrow and then back to the Dyno…….

Kevin’s been mountaineering again…

Back to Mototechnique today as I was playing Santa and an interesting visit finalising a few outstanding details.One thing which was particularly interesting and exciting is that as the paint has cured we are starting to get all the carbon wrinkle peeping through just as we were hoping, but being a full respray and with its past, never fully confident. The attached tries to show it and that is not orange peel or camera shake, the surface finish being perfect, it is just the carbon starting to grin.Not easy to photograph but hopefully you get the idea. Interesting as immediately after paint it was totally flat.Very pleased as it is occurring on all panels.

A shot from my recent visit.

Just to show that life goes on at Mototechnique even with my project winding down.

Interesting to see what 700++ HP can do to a set of rears on the dyno!

An overhead shot taken with a very wide angle lens which unfortunately distorts the front clam, and rather than tapering in as it does in reality by the doors, it appears straight. The rear also looks a bit odd but overall it still looks pretty good.

Last post for Christmas.This is the carbon tunnel control panel. The Motec unit has four Maps and we have them currently calibrated as:Position 1 600HP for everyday use

Position 2 650HP for fast road or general track use

Position 3 700++ for hard track use

Position 4 we have left free in case we decide to run race fuel when it would probably put out 850, but for how long.The great thing is that the 600HP setting is made at only approx 1.1Bar so it should be relatively unstressed for general road use.A very Happy Christmas to everyone who has, and continues, to follow this thread.

Original: Build Threads